| Our laboratory focuses on the research that handles hydrogen isotopes including

tritium which is fuel of a fusion reactor.We aim to understand elemental

phenomena that are required to develop fusion reactor, fission reactor

and next-generation energy system utilizing hydrogen, and to optimize these

systems as an aggregate of elements. Scientific education and research

about experiment and numerical analysis are conducted from the viewpoint

of process engineering. |

|

|

|

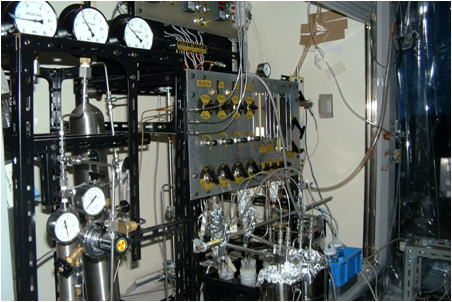

Tritium experimental room

A lot of findings have been obtained through the tritium experiment.Recently,

we are working on the quantitative understanding of the tritium behavior

in concrete materials and plasma facing materials, in addition to tritium

breeding materials.

|

|

|

|

|

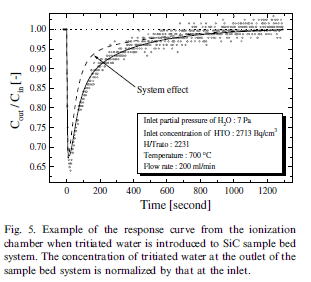

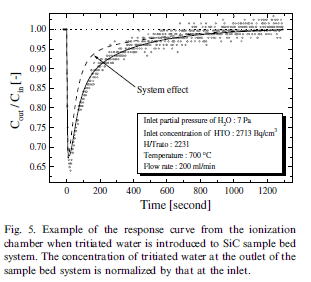

| Tritium trapping on the surface of SiC |

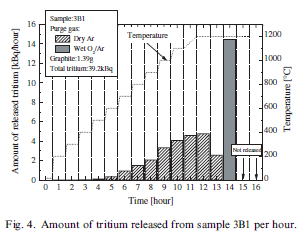

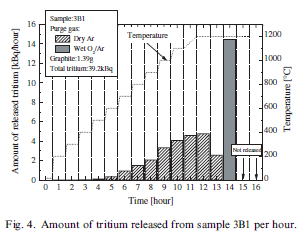

Release of tritium impranted into JT60 graphite tile |

|

|

|

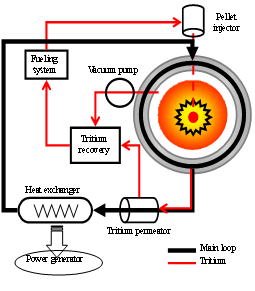

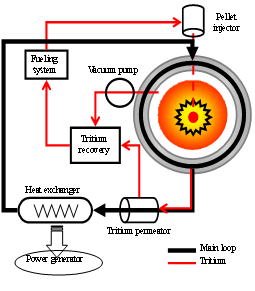

Study on behavior of hydrogen isotopes in liquid blanket.

The

blanket in a fusion reactor plays very important roles, (i) tritium breeding

for fuels supply, (ii) heat exchange for energy, (iii) shielding radiation for

safety. Liquid blanket system has some advantages such as simple blanket

structure, a high tritium-breeding ratio, a high thermal conductivity.

Candidate materials of liquid blankets are Li, Li17Pb83,

FLiBe, and so on. We study about the behavior of hydrogen isotopes in their

material, especially Li and Li17Pb83 in order to

construct a reliable tritium recovery system with low tritium leakage. The use

of Li is expected for a flowing target in the International Fusion Materials

Irradiation Facility (IFMIF) for high-intensity

neutron generation. IFMIF is designed to test materials durability under high

intensity neutron-irradiation conditions of the future commercial fusion

reactors. Our research group has been developed a Y hot trap

for remove tritium from Li loop. Li17Pb83 is one of the most

promising candidate materials for liquid blankets in fusion reactors. We are studying

about tritium behavior in Li-Pb blanket for design the tritium recovery system.

|

|

|

|

Study on tritium behavior in solid breeder materials.

under construction. |

|

|

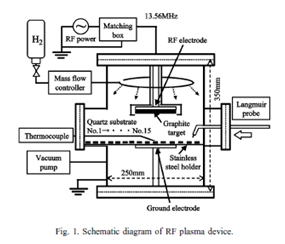

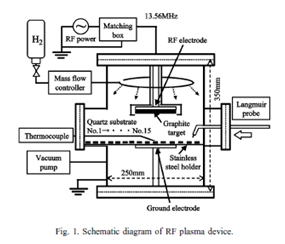

Study on tritium behavior in re-deposited layer

The plasma facing wall is eroded by interaction with high-energy particles

and impure particles are emitted to the plasma. A part of the emitted impurities

returns to the surface of the wall via some interactions with the plasma

and it forms a re-deposition layer or dust containing fuel atoms. From D-T experiments such as Joint

European Torus (JET) or Tokamak Fusion Test Reactor (TFTR), it has been

revealed that a large amount hydrogen isotope is retained in carbon-based

co-deposition. From the viewpoint of fuel recycling and

assurance of tritium safety, it is essential to understand the sorption and

desorption behavior of tritium from not only plasma facing materials but also

re-formed materials. However, discussions about tritium behavior

in tungsten a re-deposition layer have not been performed sufficiently. In this study, we made various re-deposited layers by a sputtering method using hydrogen RF plasma. The amount of hydrogen isotopes trapped in the layer is quantified. |

|

|

|

|

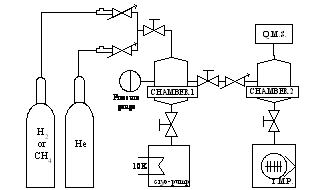

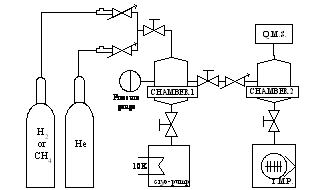

Study on desorption of hydrogen, helium and methane from cryo-sorption

pump

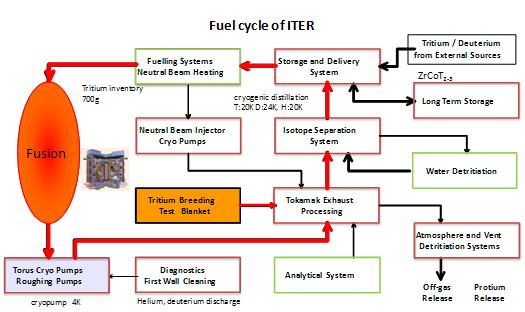

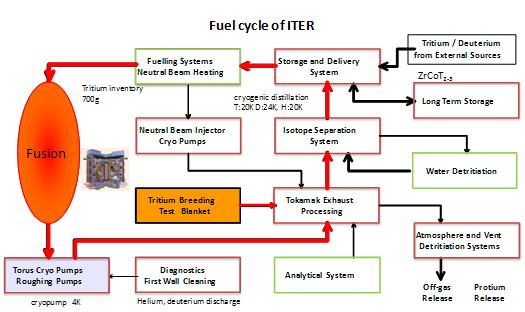

A key issue to establish the tritium (T) fuel cycle of fusion reactor systems

such as DEMO or the future commercial reactors is to reduce tritium inventory

for increasing potential safety of D-T fusion reactors. In order to do

that it is necessary to constitute a self-sufficient reactor system.The

first process of the fuel cycle after D-T burning is the evacuation of

gas mixtures including hydrogen isotopes, helium and impurities by cryo-sorption

pumps or turbo molecular pumps.The cryo-sorption pump has be used for the

evacuation system for the reasons that high magnetism tolerance and high

vacuum speed of all gases. However, the process of regeneration to discharge

the gases saved up is needed for cryo-sorption pump because that is a pump

of the saving up type. Therefore, it is necessary to examine several gas

discharge behavior from the cryo-sorption pump under various conditions. |

|

|

|

|